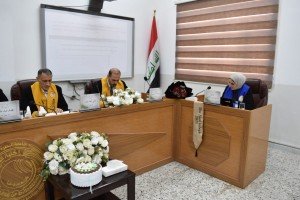

A master's thesis in the College of Engineering at the University of Basrah discussed (optimization in quenching and tempering conditions for low alloy steel AISI 4330) The thesis presented by student Hadeel Karim Abdel-Redha dealt with the use of low-alloy steel AISI 4330 to perform hardness testing, X-ray diffraction testing, chemical analyzes, and electron microscopy examinations for two cases. In the first case, the alloy was heated to temperatures from (C ֯ (800) to (C 1000). ) in steps of (C֯) 50 for holding times of (120 minutes-30) in steps of (30 minutes) and then quenched in different cooling media. For the second case, the alloy was hardened at (C֯) 250 for holding times of (30 minutes). lloy steel AISI 4330 The thesis concluded that the amount of retained austenite increases with the increase in the heating temperature (the degree of ossification) for the same cooling medium, and it also increases with the increase in the cooling rate. The maximum amount of retained austenite was found to be (7.733 wt%), which was identified when the samples were heated to (1000 C֯) and then quenched in water, while it was found that the lowest amount of retained austenite was (2.324 wt%) when the samples were heated to (1000 C C֯ (800) and quenched in oil. Using the Vickers hardness test method,